Cata Cooling shut down operations at the end of 2021. This site is for archive purposes only.

Each summer, workers face intense heat on the worksite, causing heat-related downtime, lowered productivity, and higher worker turnover.

Heat-related downtimeA single heat event that causes a worker to leave their post, even when not OSHA-reportable, can cost hundreds of dollars in lost time and follow-up.

ProductivityWorksites slow down when the heat index rises above 85F, especially in environments of high humidity, direct sunlight, or light wind. Experts estimate this contributes to labor productivity loss of up to 30%, and managers have observed that job site production can slow 10-20% on a hot summer day.

Worker turnover and satisfactionIn the long term, excessive heat can deteriorate job satisfaction, causing costly turnover.

Employers are left with rudimentary ways of dealing with the heat: water, ice, shade, and work-rest cycles.

Water and iceWorkers today rely on coolers filled with water bottles and ice to keep cool. The cold water directly regulates body temperature and supply additional fluid to replace sweat.

Passive measuresSome workers use cooling towels, which they soak in water and drape around their neck. Others make sure to wear wide-brimmed hats with neck gaiters to keep the sun off their skin.

Upgrading to active systemsWhile these techniques provide some level of heat relief, they are far less effective than the active cooling that a cooling vest can provide.

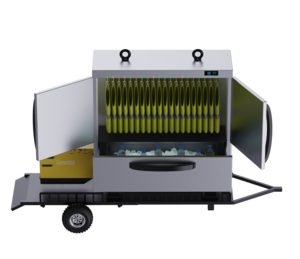

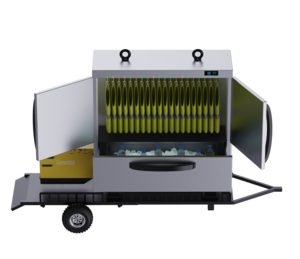

At Cata Cooling, we've developed a worker cooling service that provides a fleet of cooling vests for workers onsite. We provide freezer units, shown above, with vests for workers to stay cool throughout the entire day. Each worker is given cold vests so they can use one as another recharges. Each freezer unit provides and recharges enough cold vests for 5-10 workers. These units are highly mobile. They can be operated off of generators or plug-in power, and they are fitted with a trailer, fork lift slots for high mobility. A compact version can even fit on the bed of a pickup truck. We provide these units as a per-worker monthly subscription, so our customers only pay for what they need. We conduct regular freezer unit inspections to ensure vests and freezers are maintained.

Our solution is great for construction sites, process plants, roofing crews, and manufacturing lines.

We will be partnering with 3 companies in the summer of 2021 to run pilots and further develop our cooling systems. We would be happy to hear about your heat exposure situation and discuss how our product could serve you. Let us know if you'd like to be part of our earliest group of pilots.

Interested in active cooling solutions to the heat? Want to collaborate or learn more about our technology?

Shoot us an email at [email protected]!

We are were a team of MIT engineers hoping to bring powerful cooling solutions to workers around the world.

Isaac is now building Cartesian (indoor mapping and tracking for retail & supply chain).

Wilbur is now building Meticulate (automated business workflows).

Seiji decided to keep doing thermo calculations in his PhD at MIT (CO2-free Hydrogen production).

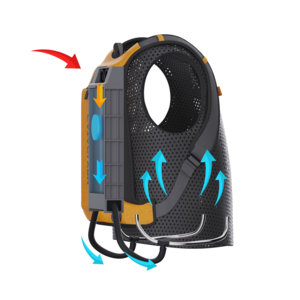

We investigated multiple approaches to wearable cooling our two years of development.

Class 2 Safety with 90 minutes of cooling

Fans would circulate cold air over a swappable ice pack and through the vest.